Robotics is an interdisciplinary subject that forms an amalgamation of different subjects to specialize in developing, inventing and deploying robots. It also refers to these robotic systems that are designed to help human beings and complete the duties that prove to be hazardous, repetitive, or otherwise inappropriate to humans to do. Robotics in the field of mechanical engineering focuses on the mechanical structure and mechanical engineering of robots. In the sphere of computer science. The focus is on algorithms and software that cause the automatization of robotic conducts. Also, robotics is an interdisciplinary discipline, which relies on expertise in electrical, electronic, control, telecommunication, mechatronics related topics, and materials science and information engineering disciplines.

The Meat in Robotics

The majority of the robotic systems are created with the consideration to either facilitate or replace the human workforce, mostly where conditions of the workplace are dangerous. The use of robots in search-and-rescue operations, space exploration, underwater or underground exploration in case of mines or in the form of ship wrecks is critical.

These are also applicable in industries that involve high stability and accuracy of outputs like automatic possibility of assembling items, observation machineries, transportation of goods and cleaning services. With technological advances, the area of technological advances and the possibilities of robotics only ever expand where inventions are made on a continuous basis to accommodate issues that arise in society or industry.

There are three Core Dimensions of Robotics!

Robotic systems tend to be designed and operated by combining three main components, namely mechanical structures, electronic systems and software logic.

Mechanical Engineering Part

This dimension consists of the physical form and construct of a robot. There is a close connection between the purpose of a robot and its appearance. As an example, a robot designed to handle uneven landscape may be designed using caterpillar treads to give it better grip. Flexible and folding structures are used in the invention of robots that can work in such harsh environments such as in origami-like robots.

Mechanical design is basically a design solution of the engineer to the functional needs, and physical requirements in which the robot would perform its duties. Here, the rule of thumb “form follows function” is critical, the form and construction depend on what the robot will be able to achieve.

Its part is with Electrical Engineering.

This component consists of power systems and circuitry to make a robot be able to move, sense, and interact. Robots still operate using electrical circuits, however, there are those that use electricity through batteries and the others use electricity through the combustion engines. Even vehicles that are mostly driven with the help of fuel will require electric starters, this is why electricity is required.

Robots use electrical systems and normally have one of the following purposes:

Electrical energy is transformed into motion by motors.

Sensing:

Sensors measure the variations in temperature, sound, light, position or the energy and send electrical messages to the control unit.

Operational control:

Power is required to perform operations and commands on a constant basis.

Even the best mechanical structure stands still unless there is any good electrical integration.

Software and Programming Element

All-over or semi-autonomous operation of a robot is solely dependent on the software system of the robot. The decision-making structures and logical commands through which and when a robot will act are supplied by the programming.

Just to give an example, even a tracked robot constructed to navigate through mud will not move an inch despite its mechanical and electrical systems being present as long as there is no program to run it. The computer program basically mimics the brain of the robot in that it determines its reactions and actions.

The software in robots would fall under the following three categories:

Remote Control (RC):

In these robots, they act directly following the instructions given out by a robot operator using a remote control device. This technique is more traditional automation than state of the art robotics.

Artificial Intelligence (AI):

These robots can recognize the environment and come to decisions using algorithms located in advance. They do not require input from a human being in real time to function independently.

Hybrid Systems:

These systems will integrate some aspects of remote control together with artificial intelligence whereby their working modes can take different formats. As an example, robots can be manually guided in cases of complicated missions but use AI to navigate or avoid an obstacle.

The Fast Growth of Robotics

Robotics is a very dynamic and fast developing branch of contemporary engineering and technology. The consumer applications list ranges from autonomous drones and self-driving cars, along with humanoid assistants and industrial robotic arms to the ones linked with the sphere of industry, the list is rapidly growing. As machine learning, sensors and miniaturized hardware gained prominence, robots are getting more efficient, smart and able to work with humans.

Real Life Uses of Robotics

The following are only some of the fields that robots are making a huge difference:

Healthcare:

Surgical robots aid the doctor in precision based procedures and rehabilitation robots aid the patient in walking again.

Agriculture:

Drone aided crop planting, monitoring and harvesting requires a few humans and manages it with robotic harvesters.

Military and Defense:

Robots are utilized in the areas of reconnaissance, bomb-clearance and even logistic requirements in dangerous lands of combat.

Warehousing and logistics:

Corporations such as Amazon also utilize an armada of mobile robots to sort and store, transport goods in a fast and effective manner.

Personal Robots at Home:

Personal robotics is increasingly becoming a household item with robotic vacuum cleaners, smart cooking aids and manufacturers of other home suite household tasks robots.

Applied Robotics

Practical Applications And Technological Applications

The world of robotics is highly customized; a lot of machines are designed to fulfill only one purpose. This renders practicality more useful to functional classification than general one. As an example, robots developed to work in assembly lines are generally not portable to other areas of application- these are referred to as assembly robots. Within the welding industry, organizations tend to provide complete robotic welding systems consisting of robot, welding equipment, and the additional support devices such as turntables. Such integrated systems may be called welding robots, although the underlying robot can be converted to other functions. On the same note, the robots that are developed to work with bulky materials are put in the following categories:heavy-duty robots.

New and Emerging Applications of Robotics

1. Manufacturing Automation

Robotics has transformed industrial manufacturing since the 1960s. As indicated by the Robotic Industries Association, in 2016, 52 of all the industrially sold robot sales were in the automotive industry. In certain automobile factories, robots have started doing most of the jobs. Indeed the Space Age facility constructed by the IBM Corporation in Texas, to produce keyboards, as of 2003 was operated as a “lights-out” plant largely unstaffed by humans.

2. Autonomous Transportation

Automated transport Robotic systems are fundamental building blocks of automated transport- examples include commercial airplane autopilot systems, and recent advances in self-driving cars.

3. Home Automation

Robots have now entered homes. Household robots have the capability of vacuum cleaning, mowing, loading dishwashers as well as preparing flatbreads.

4. Construction and Infrastructures

Construction sector robots can be divided into traditional machines, robotic arms and wearable exoskeletons to help or increase human efforts.

5. Mining Operations

It takes care of the mining operations with better safety and productivity due to automated systems that take over work.

6. Space Missions

Robotic explorers help NASA and other space organizations to analyze and collect information in extraterrestrial worlds where it is too risky or not possible to expose human lives.

7. Energy Sector

The use of robots in looking after solar energy plants and cleaning up of dangerous nuclear waste areas is significant.

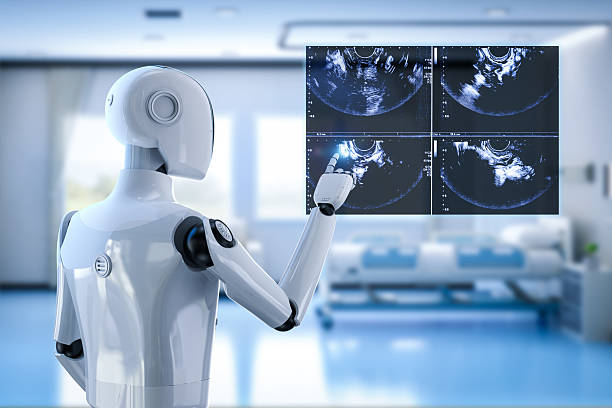

8. Clinical, Operative Uses

Robots also help in diagnostics and surgery in healthcare. These are the machines that are based on precision, which are finding greater application now in clinics and hospitals.

9. Agricultural Innovation

Agro robotics is picking up. Self-driving tractors to machine learning crop analysis and drones, advanced equipment are upending modern agriculture through the power of precision.

10. Food Technology

Computerized kitchens are on the increase. Examples include:

Flippy: a burger grilling robot

Zume: automatizes makes pizzas

Cafe X: generates and brews coffee

Makr Shakr: cocktail battering

Frobot: sells frozen yogurt

Sally: makes up salads

Food bowl robots developed by Dexai and others are also in use in military bases, as well as by startups like Spyce Kitchen (which was sold to Sweetgreen).

Robot mechanical systems

Power Sources

Robots should be powered with great focus on the choice of energy systems. Most robots today utilise rechargeable lead-acid batteries that are considered safe and long-lasting though with the increased weight. Other high-end batteries such as the silver cadmium are smaller but so much more costly.

Motion and Actuation System

The Robotic Muscles The actuators:

Actuators span the energy store to physical movement. They are the key elements in which a robot will be able to lift, push, turn or move portions of its body.

Electric Motors

Electric motors turn out to be the most frequent actuators used in robotics:

Brushed and brushless DC motors:

used in battery powered and mobile robots

AC motors:

very common in heavy industrial and CNC applications.

High-Technology Actuation and Control in the Robotics

series elastic actuators (SEAs)

Series Elastic Actuation is a method of imparting a controlled amount of stiffness between the load and the adjacent actuator (normally a motor). This soft component decreases reflected inertia and increases the safety of robotic systems, especially in the process of human contact or in case of the unpredictable collision. The extra bearing elasticity leads not only to shock absorption and energy efficiency but also to reduced wear and tear on major mechanical components. Successful implementation of this method has been witnessed in manufacturing robots and humanoid robots.

Technologies Artificial Muscle

Air Muscles (Pneumatic Artificial muscles)

It consists of inflatable tubes, which can grow, and such growth can expand up to 42 per cent, producing motion when inflated with air. They are also applied to light and soft acting robotic systems.

The concept of Shape Memory Alloys (Wire Muscles)

They are also referred to as muscle wires and on activation, they contract. Their contraction is minimal though (usually under 5%) but they can be used in small form factor robots where room and complexity is at minimum.

Robotics Sensor Technologies

Robots rely on many types of sensors to get a sense of their environments and inner conditions. The sensation is an essential input in intelligent decision-making and response to changing environments.

Robotic End-Effectors

Mechanical Grippers

Grippers are the most usual robotic devices at the end of an arm. These are normally the palmer set with two antagonist fingers that open and close to pick items. There exist variants, as simple as claw mechanisms and as sophisticated as multi fingered human-like hands like the Shadow Hand or the Robonaut hand. As-built modelsMore complex and more functional intermediate models such as the Delft Hand exist. Depending on the task, grippers may use friction or enveloping methods to fix them.

Vacuum ( Suction ) Grippers

End-effectors are especially needed in suction end-effectors which utilize vacuum services to get a grip on things. They are also commonly used in production such as transporting flat and smooth products such as windshields or circuit boards. They are particularly applicable where visual systems give inaccurate placement of an object. Soft suction cups are adaptable to the object they are applied to even when a small error inaccuracy is present.

Robotics Control Systems

It seems that Robotic Control is beneficial to grasp a fuller picture of it being a forceful entry in the restaurant business.

In controlling a robot, there is a perception, processing and action cycle. The data is obtained by sensors situated in the body of the robot (or in the environment) and include, first, such values as joint angles or position of the tool. Thereafter, the data is interpreted whether raw or the filtered models, to judge on the action. Lastly are control algorithms which issue commands to motors or actuators in order to achieve motion.

Examples include:

- RuBot II has the capability of solving Rubik cubes with the ability of combining side sensing, planning and precision control.

- Puppet Magnus, a marionette operated by robotics, which shows the concept of combining sophisticated locomotion in creative expression.

Conclusion

A powerful interdisciplinary approach, robotics integrates mechanical engineering, electronics, computer science and control systems in order to create machines that can work in a wide variety of environments to complete tasks. Modern robotics is continually changing with series elastic actuators and smart artificial muscles on one hand and intelligent sensing and control systems on the other. All these kinds of innovations are facilitating robots working with humans in a more secure, effective, and clever way in factories, households, clinics/hospitals, and even in distant space. With improvements in technology, robotics will become a central phenomenon in productivity, safety, and improvement in the quality of life in industries and daily life.

FAQS

1. What are the series elastic actuators and why would we care about them in robotics?

Answer:

With a deliberate elastic component between motor and load, series elastic actuators (SEA) can absorb peak loads, as would happen in hydraulic or pneumatic actuators. The design also boosts the safety and performance of physical interaction with a human being or object since it limits reflected inertia and boosts force control.

2. What are the ways of perception that robots have?

Answer:

Sensors such as tactile sensors, cameras, lidar, radar and sonar are used by robots to sense information about the components of their environment. Robots equipped with these sensors are able to interpret and react to real world environments. This robotic precision and safety ensure accurate operation.

3. How can you compare air muscles and wire muscles as far as robotics is concerned?

Answer:

Air muscles are pneumatic muscles which inflate under pressure of the air extracted through them and provide a soft or flexible movement. Shape memory alloys (wire muscles), are alloys that will contract a little when an electric current is applied. The two simulate bodily movements of muscles and are distinct in terms of strength, velocity and usage.

4. So what is a robotic end-effector and what common types are there?

Answer:

The tools or devices at the end of the robotic arm which are used in interacting with the environment are called end-effectors. Well-known examples are mechanical grippers, suction cups and humanoid hands all of which are applicable at different tasks such as gripping, lifting, and handling.

5. What controls motion in the robots?

Answer:

The way robots are moved is the way of sensing, processing and actuation. Sensors measure, processors calculate what must be done, and then actuators move the robot–generally with the help of control theory and motion planning algorithms.